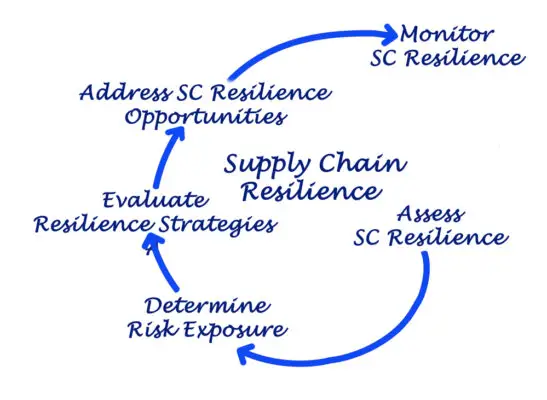

Building a resilient supply chain is essential for businesses to ensure that they can withstand various disruptions, including natural disasters, geopolitical conflicts, global health crises, and other unforeseen circumstances. Here are some steps you can follow to build a more resilient supply chain:

Risk Assessment: Identify potential risks and vulnerabilities in your supply chain. This could be geopolitical risks, climate-related risks, single points of failure, reliance on a single supplier, etc. This process involves mapping out your supply chain, understanding where disruptions might occur, and estimating the impact of such disruptions.

Diversify Suppliers: Avoid dependency on a single supplier or region. Establish relationships with multiple suppliers in diverse locations to avoid being affected by a crisis in one area.

Inventory Management: Consider holding safety or strategic stock to buffer against supply chain disruptions. However, you should balance this against the carrying costs of inventory.

Technology Integration: Use supply chain management systems and other technological tools to increase visibility and enhance communication within your supply chain. This can also help you track performance, predict potential disruptions, and make more informed decisions.

Flexibility: Design your supply chain to adapt to changes quickly. This could involve using multiple transportation modes, creating flexible manufacturing processes, or implementing responsive logistics strategies.

Collaboration and Relationship Building: Build strong relationships with your suppliers and collaborate closely with them. Sharing information and aligning goals can improve visibility, trust, and resilience.

Contingency Planning: Develop contingency plans for various types of disruptions. This involves creating procedures to manage crises, designating crisis management teams, and regularly testing these plans to ensure they are effective.

Continuous Monitoring and Improvement: Monitor your supply chain and learn from disruptions. This involves analyzing performance, identifying areas for improvement, implementing changes, and continuously reassessing risks and plans.

Training and Education: Ensure that employees understand the importance of supply chain resilience and are trained in risk management procedures and contingency plans.

Sustainability: Focus on building a sustainable supply chain, as sustainability challenges can also pose significant risks. This can involve addressing environmental issues, ensuring good labor practices, and maintaining good community relationships.

Building a resilient supply chain is a strategic initiative that involves assessing and mitigating risks, making informed decisions, and continuously improving and adapting to new information and circumstances.

In today’s globalized economy, the resilience of supply chains has become an essential aspect of business operations. The COVID-19 pandemic has exposed vulnerabilities in supply chain systems worldwide, highlighting the need for businesses to build robust and agile supply chains that can withstand unexpected disruptions.

A resilient supply chain ensures business continuity and sustainability, making it a critical factor for success in a complex and uncertain world. This article explores the key principles and practices of building a resilient supply chain.

It delves into the challenges businesses face in achieving this goal, including balancing cost-effectiveness with resilience and streamlining operations while maintaining quality standards.

Additionally, it discusses innovative solutions like OrderTron that can help businesses achieve greater efficiency and flexibility in their supply chain management.

Creating a Pivoting Supply Chain

In the context of the Supply Chain Resilience Initiative and challenges faced by the Australian food sector, one strategy for building supply chain resilience is to create a pivoting supply chain that emphasizes geographic makeup, planning capability, supplier landscape, inbound and outbound logistics, and financial health.

A pivoting supply chain involves building flexibility into every aspect of the supply chain so that it can quickly adapt to changes in demand or disruptions in the system. This approach requires understanding all aspects of the supply chain and developing contingency plans for each potential disruption.

Suppliers need to focus on several key areas to create a pivoting supply chain that is resilient to disruptions. Geographic makeup refers to identifying potential sources of disruption based on location and diversifying suppliers across different regions.

Planning capability involves forecasting demand and inventory levels accurately while also developing contingency plans for unexpected events. The supplier landscape involves evaluating supplier risk by assessing their financial stability, reputation, and ability to deliver products consistently.

Inbound and outbound logistics involve optimizing transportation routes, modes of transportation, storage facilities, delivery times, and safety measures.

Creating a pivoting supply chain is essential for building resiliency in today’s complex business environment. Focusing on geographic makeup, planning capability, supplier landscape, inbound and outbound logistics, and sound financial health practices will increase efficiency while minimizing risks associated with external shocks such as natural disasters or geopolitical instability.

The key takeaway is that businesses must be proactive about building resilient supply chains rather than waiting until something goes wrong before taking action.

Achieving Cost-Resilience Balance

Achieving a balance between cost efficiency and the ability to withstand disruptions is crucial for suppliers seeking to strengthen their operations in the face of challenges within their respective industries.

Suppliers must focus on several key areas to achieve this balance, including geographic makeup, planning capability, supplier landscape, inbound and outbound logistics, and financial health.

One way for suppliers to achieve cost-resilience balance is by conducting a thorough analysis of their geographic makeup. This includes identifying potential risks, such as natural disasters or political instability in certain regions, which may affect supply chain operations.

Additionally, it involves evaluating transportation costs associated with different regions and determining the optimal locations for production facilities and warehouses.

Another important factor in achieving a cost-resilience balance is effective planning capability. Suppliers should have contingency plans for disruptions such as natural disasters or pandemics.

These plans should include alternative sourcing strategies and backup inventory management systems. Furthermore, suppliers should regularly review their plans to ensure they remain relevant and up-to-date with changing market conditions.

Building a resilient supply chain requires careful consideration of cost efficiency and the ability to withstand disruptions.

To achieve this balance, suppliers must focus on key areas such as geographic makeup, planning capability, supplier landscape, inbound and outbound logistics, and financial health.

Streamlining Operations with OrderTron

The order management solution, OrderTron, can streamline the operations of food suppliers by providing comprehensive features that improve their capacity and sense and pivot capability, ultimately saving time and money.

With OrderTron, suppliers can easily manage orders in real-time, monitor inventory levels, track deliveries, and generate reports for better decision-making. Additionally, the platform offers a user-friendly interface that is easy for suppliers and customers to navigate.

OrderTron’s capabilities go beyond just streamlining operations. It also helps food suppliers build a resilient supply chain by eliminating manual errors and reducing delays in order fulfillment.

The platform allows suppliers to automate their ordering process while ensuring data entry accuracy easily. This not only saves time but also minimizes the risk of human error.

Building a resilient supply chain has become imperative for food suppliers in today’s fast-paced business environment, where disruptions are becoming more common. They can achieve this goal by using OrderTron as an order management solution while remaining cost-efficient.

The platform’s comprehensive features enable them to streamline their operations while its automation capabilities help them respond quickly to changes in demand or supply. Ultimately, this leads to increased customer satisfaction and growth opportunities for food businesses in Australia.

| Benefits of Using OrderTron |

|---|

| Streamlines Operations |

| Saves Time & Money |

| Improves Capacity |

Comprehensive Features of OrderTron

OrderTron offers an array of features that enable food suppliers to manage their orders efficiently and accurately, meet customer demand, and improve the overall performance of their operations.

One of the key features of OrderTron is its ability to automate order processing, which can save suppliers time and reduce errors associated with manual data entry. With OrderTron’s automated order processing capabilities, suppliers can receive orders from multiple channels (e.g., email, phone) in one central location and automatically process them into their inventory management system.

Another key feature of OrderTron is its real-time inventory tracking capabilities. With this feature, suppliers can easily monitor their inventory levels and proactively decide when to reorder products.

This helps to avoid stockouts or overstocking situations that can negatively impact a supplier’s bottom line. Additionally, OrderTron’s real-time inventory tracking capabilities allow suppliers to provide customers with accurate information about product availability, which can help build trust and loyalty.

Lastly, OrderTron offers advanced reporting tools that allow suppliers to gain insights into their business performance. These tools provide detailed information about sales trends, order fulfillment rates, and customer behavior patterns.

Through analyzing this data, suppliers can identify areas where they need to improve their operations and make informed decisions about how best to allocate resources in the future.

These comprehensive features offered by OrderTron are essential for building a resilient supply chain capable of meeting the demands of today’s fast-paced business environment.

Contact OrderTron for More Information

To learn more about how food suppliers can improve their operations and meet customer demand, it is recommended to contact OrderTron for additional information on its comprehensive features and benefits.

As a unique order management solution designed specifically for Australian food suppliers, OrderTron offers a range of tools that can help businesses streamline their operations and build supply chain resilience.

Suppliers can save time and money by using the most affordable, efficient, and effective wholesale ordering solution in Australia while gaining sense and pivot capability.

OrderTron’s comprehensive features are tailored to the needs of Australian food suppliers. With easy-to-use software, businesses can manage orders efficiently while keeping track of inventory levels in real time.

The platform also provides insights into customer behavior through detailed analytics, allowing businesses to make data-driven pricing strategies or product selection decisions. Additionally, OrderTron offers seamless integration with existing systems, such as accounting software or point-of-sale systems.

In addition to its comprehensive features, OrderTron offers expert advice on best practices for managing supply chain disruptions such as those caused by COVID-19 or other external factors.

Its focus on innovation and efficiency, OrderTron is committed to helping Australian food businesses thrive in an increasingly competitive market by providing the tools they need to succeed.

Frequently Asked Questions

What are some specific examples of disruptions that the Australian food sector has faced in recent years?

The Australian food sector faced disruptions due to bushfires, the COVID-19 pandemic, and ransomware attacks. Such incidents highlighted the need for a resilient supply chain that can withstand various challenges and ensure food security in the country.

How do demographic shifts and urbanization affect the food supply chain?

Demographic shifts and urbanization are causing changes in the food supply chain. The increasing population density in urban areas leads to a shift towards smaller, more frequent deliveries, which can increase costs and create logistical challenges for suppliers.

Are there any specific regulations or legislation in place to manage the manufacturing, distribution, or food sales in case of emergency in Australia?

Australia doesn’t have specific legislation to regulate or manage food manufacturing, distribution, or sales during emergencies. However, government departments work with industry to ensure the food supply’s security, continuity, and safety. A $10 million fund has been created for building resilience in the food sector.

How does OrderTron help suppliers streamline their operations and build supply chain resilience?

OrderTron helps suppliers streamline their operations and build supply chain resilience by providing an order management solution that improves capacity, sense, and pivot capability. It saves time and money through affordable, efficient, and effective wholesale ordering.

Are there any case studies or success stories of suppliers who have used OrderTron to improve their supply chain resilience?

No specific case study or success story is available on how OrderTron has helped suppliers improve their supply chain resilience.

However, its features, such as streamlining operations, improving capacity, and providing affordable wholesale ordering solutions, can potentially aid in building a resilient supply chain.

Conclusion

Building a resilient supply chain is crucial in ensuring business continuity and sustainability in today’s complex and uncertain world. The Supply Chain Resilience Initiative, a collaborative effort between Australia, India, and Japan, promotes best practice national supply chain policy and principles in the Indo-Pacific region.

However, challenges and disruptions to the supply chain can arise unexpectedly, such as those faced by the Australian food sector during the COVID-19 pandemic.

To address these challenges and build a resilient supply chain, businesses can consider pivoting their operations to adapt to changing demand patterns and achieving a balance between cost resilience. Innovative solutions like OrderTron can also streamline operations through its comprehensive features.

Through adopting these measures, businesses can improve their ability to withstand unexpected shocks and challenges while maintaining their competitiveness in the market. Contact OrderTron for more information on how it can help your business build a more resilient supply chain.

Chris Ekai is a Risk Management expert with over 10 years of experience in the field. He has a Master’s(MSc) degree in Risk Management from University of Portsmouth and is a CPA and Finance professional. He currently works as a Content Manager at Risk Publishing, writing about Enterprise Risk Management, Business Continuity Management and Project Management.