The supply chain industry has been facing unprecedented challenges recently, leading to a crisis that has been felt across various sectors. The COVID-19 Pandemic has been the primary driver of the disruptions, causing a ripple effect that has impacted supply chains globally. Some of the reasons include;-

COVID-19 Pandemic: The pandemic has disrupted global supply chains in unprecedented ways. Many factories had to shut down or reduce production due to health and safety concerns. This led to a decrease in the supply of various goods.

At the same time, demand for certain products increased as people’s lifestyles changed due to lockdowns and remote work, leading to a mismatch between supply and demand.

Labour Shortages: Many sectors, including transportation and manufacturing, have faced labour shortages due to the pandemic. This has slowed down the production and delivery of goods.

Shipping Disruptions: There have been significant disruptions in shipping due to various factors. These include a shortage of shipping containers, congestion at ports due to increased demand and reduced capacity, and even incidents like blocking the Suez Canal in early 2021.

Increased Demand: As economies recover from the pandemic, demand for goods has surged. However, the supply chain has been unable to keep up with this increased demand, leading to shortages and delays.

Raw Material Shortages: There have been shortages of various raw materials, partly due to production disruptions caused by the pandemic and partly due to increased demand. This has affected the production of a wide range of goods.

Geopolitical Issues: Trade and geopolitical tensions have also contributed to the supply chain crisis. For example, trade disputes between major economies can lead to tariffs and other barriers that disrupt the flow of goods.

The industry has faced many challenges, including labour shortages, transportation disruptions, and natural disasters, all of which have contributed to the crisis. This article explores the various factors that have led to the current supply chain crisis.

We will analyze the impact of COVID-19 on the industry, the labour shortages and transportation disruptions that have played a significant role in the crisis, and the impact of natural disasters.

Additionally, we will examine strategies that businesses can implement to overcome the challenges and mitigate future disruptions.

Understanding the root causes of this crisis will make businesses better prepared for future disruptions and develop strategies to minimize their impact.

Impact of COVID-19 on the Supply Chain Industry

The COVID-19 pandemic has profoundly impacted the global supply chain industry, disrupting production and logistics processes and causing widespread shortages of essential goods.

The crisis exposed the vulnerabilities of the supply chain system, as many countries depend heavily on imports for their essential goods.

With the imposition of lockdowns and travel restrictions, many countries’ economies came to a halt, leading to a significant reduction in demand for non-essential goods and services. This led to a ripple effect across the global chain, causing delays and disruptions in delivering goods and services.

The pandemic has also severely impacted international trade, with many countries imposing trade restrictions and export bans on essential goods. This has led to shortages of essential goods in many countries, including medical supplies, food, and other critical items.

The pandemic has highlighted the need for countries to build more resilient and diversified supply chains to reduce their dependence on imports and ensure the continuity of essential supplies during a crisis.

The COVID-19 pandemic has exposed the vulnerabilities of the global supply chain system, highlighting the need for more robust and diversified supply chains.

The crisis has shown that the system is highly interconnected, and disruptions in one part of the system can quickly cause ripple effects across the entire chain.

Governments and businesses need to work together to build more resilient and sustainable supply chains that can withstand future crises and ensure the continuity of essential supplies.

Labour Shortages and Their Effect on the Supply Chain

Labour shortages have emerged as a significant challenge for industries reliant on a steady workforce, leading to disruptions in the production and distribution of goods and services. The supply chain industry has been hit hard by labour shortages, with many companies struggling to find skilled workers to fill critical positions.

The COVID-19 pandemic has exacerbated the situation, with many workers leaving their jobs due to concerns about safety and health. Worker retention has become a critical issue for supply chain companies.

Many businesses are investing in training initiatives to help retain their workers and attract new ones. These initiatives include providing additional training and development opportunities and offering more competitive wages and benefits packages.

However, some companies are still struggling to keep up with demand, and the labour shortage will likely persist for the foreseeable future. The labour shortage is a significant challenge that the supply chain industry must address in the coming years.

Companies must focus on worker retention and training initiatives to ensure they have the skilled workforce they need to keep up with demand. It is also important for policymakers to address the underlying issues that contribute to the labour shortage, such as immigration policy and education and training programs, to help ensure that the industry can continue to thrive in the years ahead.

Transportation Disruptions and Their Role in the Crisis

Transportation disruptions have caused significant challenges for industries reliant on moving goods and services, leading to delays, increased costs, and uncertainty in the supply of essential products.

Container shortages and port congestion are two main factors contributing to transportation bottlenecks. Container shortages result from imbalances in global trade, with many containers being stuck in certain areas due to the pandemic-related disruptions. This has led to a shortage of containers in other areas, causing delays and increased costs for transportation.

Port congestion is another significant challenge that has resulted from transportation disruptions. With more goods being shipped than ever, many ports are experiencing congestion and delays getting goods in and out.

This has led to significant increases in transportation costs, with many companies having to pay higher prices for expedited shipping to ensure that their goods arrive on time.

Addressing these transportation bottlenecks will resolve the current crisis.

Transportation disruptions have played a significant role in the current crisis. Container shortages and port congestion are two main factors contributing to transportation bottlenecks, causing delays, increased costs, and uncertainty in the supply of essential products.

Natural Disasters and Their Impact on the Supply Chain

Natural disasters, such as hurricanes, earthquakes, and wildfires, can significantly impact global chains due to their potential to disrupt transportation networks and damage critical infrastructure.

These disruptions can range from temporary delays to long-term damage that can take months or even years to repair. In addition to transportation disruptions, natural disasters can cause power outages, communication failures, and other logistical challenges, making it difficult for companies to maintain their supply chain operations.

Disruptions caused by weather events have become increasingly common in recent years due in part to the effects of climate change. According to a report by the United Nations Office for Disaster Risk Reduction, the number of weather-related disasters has increased by 35% over the past two decades.

This trend is expected to continue, putting more pressure on global supply chains. In addition to weather-related disruptions, supply chains face challenges due to global trade tensions, which have led to increased tariffs and other trade barriers that can make it difficult for companies to move goods across borders.

To better understand the impact of natural disasters on the supply chain, it is helpful to examine some specific examples. For instance, the earthquake and tsunami that struck Japan in 2011 caused significant disruptions to the country’s supply chain, particularly in the automotive and electronics industries.

The disaster damaged key infrastructure, such as ports and highways, and caused power outages that affected manufacturing operations. Similarly, Hurricane Katrina struck the United States in 2005, causing widespread damage to the Gulf Coast region and disrupting supply chains for various industries, including oil and gas, chemicals, and agriculture.

In both cases, the disruptions caused by natural disasters had ripple effects throughout the global supply chain, highlighting the importance of building resilience and redundancy in supply chain operations.

| Advantages | Disadvantages |

|---|---|

| -Improved disaster preparedness | -Cost of implementing disaster preparedness |

| -Minimizes supply chain disruptions | -Difficulty in assessing risk |

| -Increased customer satisfaction | -Difficulty in predicting natural disasters |

| -Reduced financial losses | -Difficulty in coordinating with suppliers |

Strategies for Overcoming the Supply Chain Crisis

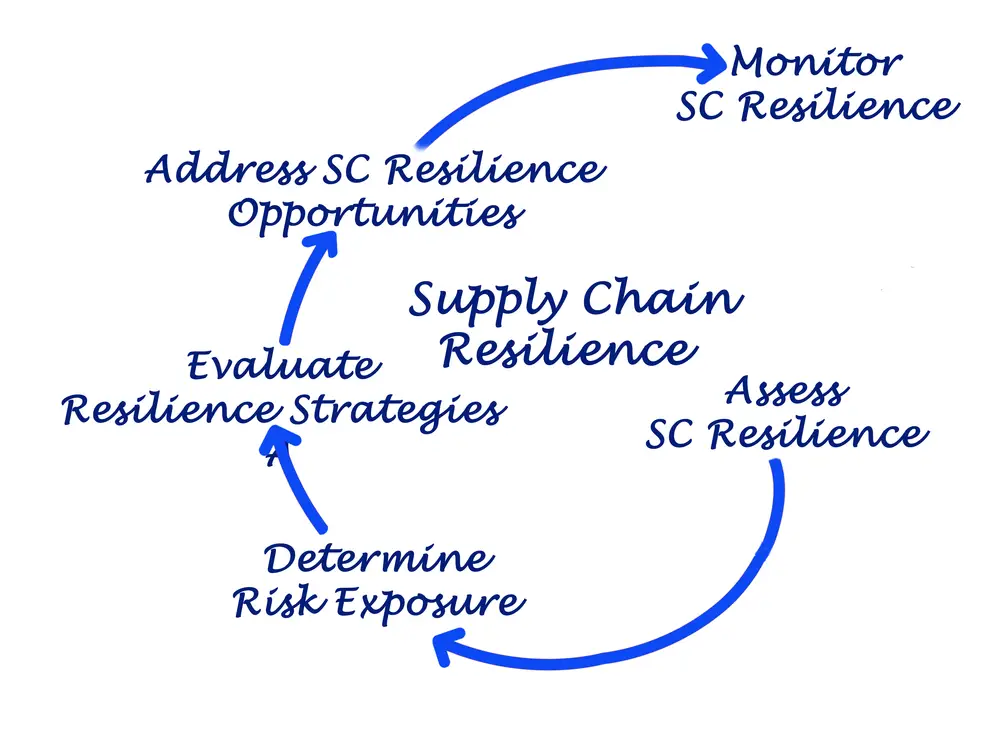

One key approach to mitigating the impact of supply chain disruptions is to focus on building resilience and redundancy in operations through proactive risk management and diversification strategies.

Collaborative innovation can help companies to identify and address risks along the supply chain by sharing information and resources with partners in the network. Companies can develop more effective risk mitigation strategies and improve their overall resilience by working together.

Digitalization solutions can also play a critical role in helping companies to overcome supply chain disruptions. By leveraging technologies such as artificial intelligence, machine learning, and blockchain, companies can improve their visibility into the supply chain and identify potential risks before they become major issues.

Digitalization can also help companies optimize their inventory levels, reduce lead times, and improve their efficiency.

In addition to these strategies, companies can take a proactive risk management approach by investing in training, education, and contingency planning. By developing a culture of risk awareness and preparedness, companies can better navigate the challenges of supply chain disruptions and ensure they are well-positioned to respond to future disruptions.

A holistic approach to supply chain management and investing in resilience, companies can minimize the impact of disruptions and maintain business continuity in the face of adversity.

Frequently Asked Questions

What industries or sectors have been most affected by the supply chain crisis, and why?

The crisis has impacted various sectors, including automotive, electronics, and healthcare. Factors such as disruptions in production, transportation, and labour shortages have contributed to the crisis. Startups can mitigate the impact by diversifying suppliers and adopting digital solutions.

How have consumer behaviours and preferences changed during the pandemic, and how has this impacted the supply chain?

Consumer trends during the pandemic have increased demand for certain goods, causing supply chain disruptions. Supply chain adaptation has been necessary to adjust to changing consumer preferences, such as online shopping and home delivery.

What steps are companies and governments taking to address the labour shortages in the supply chain industry?

Companies and governments are implementing policies and incentives to address labour shortages in the supply chain industry. These measures include increasing wages, providing benefits, and offering training programs to attract and retain workers.

Are there any long-term implications or lasting effects of the supply chain crisis beyond the pandemic?

The crisis may have lasting effects on the economy, including disrupted trade flows, higher prices, and reduced consumer confidence. The pandemic has exposed vulnerabilities in global supply chains, highlighting the need for greater resilience and diversification.

How can small businesses and startups navigate the supply chain crisis, particularly with limited resources and supply chain experience?

Small businesses and startups can navigate the supply chain crisis by exploring collaboration opportunities with other businesses, implementing efficiency strategies such as just-in-time inventory management, and diversifying their suppliers and transportation modes to minimize risk and increase flexibility.

Conclusion

The current supply chain crisis results from a combination of factors, with the COVID-19 pandemic being the primary cause. The pandemic has led to numerous challenges, including labour shortages, transportation disruptions, and natural disasters. This has resulted in a shortage of goods and raw materials, increased costs, and longer lead times.

To overcome the crisis, companies must adopt strategies such as diversifying their supplier base, investing in technology, and collaborating with their partners.

Labour shortages are among the most significant impacts of the pandemic on the supply chain industry. This has been due to various factors, including illness among workers, government restrictions, and a lack of available workers.

Companies have had to adapt by implementing new safety protocols, increasing wages, and offering incentives to attract workers.

Additionally, transportation disruptions have been a major challenge, with increased demand for goods leading to congestion at ports and shortages of shipping containers. Natural disasters such as hurricanes and wildfires have also significantly impacted the supply chain, disrupting transportation routes and causing damage to infrastructure.

Companies need to take a collaborative and proactive approach to overcome the supply chain crisis. This involves working closely with suppliers and partners to identify potential risks and develop contingency plans.

Diversifying the supplier base can also help reduce disruptions’ impact in one area. Investing in technology such as automation and data analytics can help to improve efficiency and reduce costs. Finally, companies can also consider strategic partnerships or mergers to increase their resilience and adaptability in the face of future challenges.

Chris Ekai is a Risk Management expert with over 10 years of experience in the field. He has a Master’s(MSc) degree in Risk Management from University of Portsmouth and is a CPA and Finance professional. He currently works as a Content Manager at Risk Publishing, writing about Enterprise Risk Management, Business Continuity Management and Project Management.