The rapid progression of technology has resulted in transformative shifts in various sectors of the global economy, with the supply chain industry being one of the most profoundly affected.

The digitalization of processes, enhanced by AI, machine learning, and other cutting-edge technologies, has significantly evolved how goods and services are managed and delivered.

Simultaneously, an ever-increasing demand for environmental sustainability contributes to reshaping supply chain strategies. With the threat of unforeseen global disruptions ever-present, robust risk management practices become a pivotal component of supply chain stability.

Furthermore, integrating data analytics into these operations promises more informed, efficient decision-making processes, shifting from a generally supply-driven model to a more demand-driven one.

This article will delve into these pivotal aspects of modern supply chain management.

The Dawning of Digital Transformation in Supply Chain

The reverberations of digital transformation echo across industries, shaking up established norms and turning conventional wisdom on its head. No sector stands unaffected by this powerful wave, but there’s perhaps none so prolifically impacted as the supply chain.

Digitalization is crafting the future for supply chain businesses, leaving those adaptive enough to ride the crest of innovation ahead.

From expediting processes to reshaping the very nuts and bolts of the industry, the digital revolution is carving out a landscape that is both complex and exciting.

At the heart of this revolution? Smart automation. A game-changer, no less, automation bestows the priceless advantage of speed and efficiency.

The ‘just-in-time’ model relies on carefully timed delivery systems, something unattainable without a high degree of automation. Think automatic warehousing solutions, robotics, and even self-driving vehicles – it’s a brave new world that breaks barriers to new levels of productivity.

Another integral piece of the puzzle is Big Data analytics. In an industry where precision is everything, the ability to predict and respond to market demands can make the difference between success and failure.

Big Data provides these crucial insights, from forecasting demand to uncovering inefficiencies in the supply chain, enhancing decision-making that drives businesses forward. Hail the rise of data-driven strategies!

Let’s not forget the Internet of Things (IoT). It has tightened the window between product dispatch and delivery, minimized errors, and significantly improved traceability. The interconnectivity that IoT advocates have proffered a level of visibility previously unthinkable, enabling businesses to keep a hawk’s eye on the product from factory to customer.

Blockchain, too, is making its presence felt in the industry. Gone are the days of cumbersome, paper-laden processes. Welcome to the age of a streamlined, trust-oriented supply chain continuum with cost reductions and expedited transactions.

Blockchain’s inherent transparency and security are recalibrating trust and accountability across supply chain networks, becoming an industry standard before our very eyes.

Artificial Intelligence, an undoubted marvel of this digital age, augments reality from booking orders to warehousing, transportation, and delivery. With capabilities like machine learning and predictive analytics, AI is not just driving efficiency and accuracy but also redefining jobs within the supply chain sphere.

Undeniably, the digital transformation reimagining the landscape is a magnificent tapestry of disruptive technology and innovative solutions.

Yet, it is an unfolded story – one that will pen more chapters as technology matures and businesses adapt. The key to navigating these changes lies in embracing risk, fostering flexibility, and investing in digital capability.

These are both volatile and exciting times where adaptability and innovation will set apart the leaders from the followers.

Incorporating Environmental Sustainability in Supply Chain

The Green Shift: The Imperative Role of Environmental Sustainability in Modern Supply Chain Management

Tossing the traditional navigational compass, the contemporary supply chain globe has set its course by the transformative compass of technology.

Innovation has made us stride past the era of manual ledger entries to sophisticated Just-In-Time deliveries, Big Data analytics, Blockchain applications, and Artificial Intelligence (AI) solutions.

However, without incorporating sustainability in its initiative, the supply chain’s digital revolution might be spinning its wheels without creating the substantial traction required for 360-degree transformation.

Today’s eagle-eyed consumers, robust regulations, and a throbbing global conscience insist on the critical role of environmental sustainability in supply chain management.

Is sustainability just a buzzword, or does it have a tangible effect? While it might be trendy to see sustainability as just the latest buzzword, statistics suggest otherwise.

Studies show that nearly 76% of consumers around the globe are willing to pay a premium for ‘green’ products, an uptick from 50% just five years ago.

Supply chain sustainability is not just about survival; it is about thriving and gaining a competitive edge. Businesses must understand that environmental stewardship woven into a supply chain’s fabric is not an ancillary decoration but the main thread holding everything together.

In a world where green innovations and solutions are becoming increasingly profitable, supply chains must leverage this trend smartly. Incorporating environmental sustainability into supply chain management necessitates strategic planning and synchronization.

One way is by incorporating sustainable materials procurement. As an integral part of the supply chain, sourcing materials responsibly makes a world of difference.

Waste management is another area where innovative solutions can be implemented. From recycling strategies to reducing emission footprints, sustainable waste management is a must-do strategy.

Moreover, the carbon footprint from transportation is an area that requires significant rethinking. Using intelligent route-planning software, leveraging electric or hybrid fleets, and optimizing cargo loads to minimize trips are some ways to green the supply chain’s transportation link.

Is the move towards a sustainable supply chain easy? Absolutely not. But is it worth the momentous change? Unquestionably, yes.

Companies that shift from a linear to a more sustainable, circular supply chain witness not just minimized environmental damage but also substantial cost savings and enhanced brand reputation.

In this context, those who dare to lead the green revolution in the supply chain and logistics sphere will find themselves standing ahead of the curve, setting the pace for others to follow.

In conclusion, adaptability and sustainability have become the two primary currencies of the modern supply chain marketplace.

Undeniably, no supply chain can run at its maximum potential without recognizing and acting upon the need for environmental sustainability.

In the race towards redefining the rules of the game, those who learn to harmonize with the rhythms of nature while optimizing efficiency and profitability will emerge as the flag-bearers of innovation in supply chain management.

Risk Management in the Supply Chain

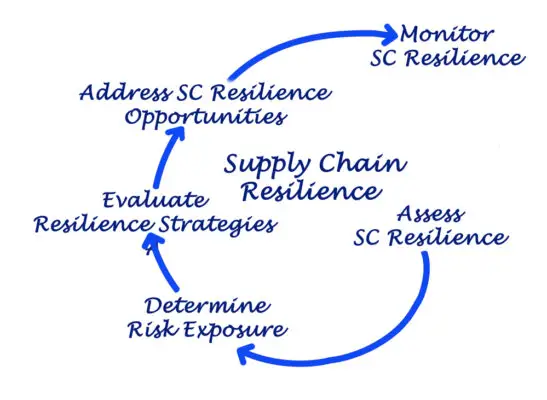

The world is abuzz with the phrase “Unforeseen Circumstances.” Yet, it’s business as usual for supply chain leaders who have been sublime in navigating the tumultuous terrain. The key to their unwavering resilience? Effective risk management.

No longer viewed through an antiquated lens, risk management has been catapulted to the forefront of business strategy. A comprehensive, sophisticated approach to risk management can arm companies with the armor of resilience to withstand storms and pave their path to continued growth.

A robust supply chain is undeniably intertwined with resilient risk management, which isn’t simply about mitigating risks. It’s about embracing them, harnessing them as vehicles of growth, and weaving them intrinsically into the strategic fabric of the organization.

The first resource in the arsenal of effective risk management is embedded agility. Like a sturdy tree bending in the wind, supply chains need to have the flexibility to adapt quickly to disruptions without breaking.

Predictive modeling can provide the insights required to adjust to shifts, maintaining a balance and continuity that ensures the delivery of critical resources.

Simultaneously, a multi-tiered supply chain strategy no longer remains an option; it serves as a prerequisite against global uncertainties.

The world has seen the cautionary tales of over-reliance on a single vendor or geography; diversity in this regard ensures an equilibrium in the supply-demand dynamic.

Equally pivotal is the role of partnerships and alliances in cementing the cornerstone of resilient supply chains. In an era where collaboration and competition blur into ‘co-opetition,’ symbiotic, mutually beneficial relationships can foster shared innovation, mitigate risks, and smoothen the flow of goods and services.

Effective risk management also requires taking a proactive stance toward cybersecurity. The heightened reliance on technology calls for strengthened defenses to thwart the escalating threats.

A robust cybersecurity framework doesn’t detract from the performance; it acts as a catalyst to enhance customer trust, bolster reputation, and prove instrumental in stakeholder confidence.

Delving deeper, financial resilience is indispensable amidst fluctuating currencies, changing tax algorithms, and the emergence of economic blocs.

Resilient supply chains are those with a financial risk mitigation strategy ingrained, aided by thorough analyses and comprehensive predictions.

Nitpicking further, talent management and skill upgrading form a crucial part of effective risk management strategies. People are the motors that keep supply chains humming.

Thus, future-proofing every node of your supply chain entails cultivating a talent pool equipped to adapt and thrive in an ever-transforming digital age.

Lastly, consideration must be extended beyond the confines of the company. Sound corporate social responsibility practices, coupled with sustainable strategies, build immunity against the fickleness of social sentiment and regulatory tides while maximally contributing to the much-needed universal objective of a greener Earth.

In essence, for supply chains to ride the wave of global uncertainties rather than be crushed by them, an amalgamation of numerous strategies under the umbrella of risk management remains crucial.

An effective risk management framework, therefore, doesn’t serve as an overlay; it forms the fundamental underlay of a supply chain robust enough to not just withstand but thrive amidst global uncertainties. This is not merely a prediction – it’s a directive for the future.

The Power of Data Analytics in Supply Chain

Sailing the Data Ocean: Decoding the Power of Analytics in Supply Chain Optimization

Capitalizing on the surging currents of data to streamline these is no longer a luxury—it is a necessity. Laser-sharp vision and entrepreneurial skills are required to navigate the complex matrix of data analytics. Molding this chaos into valuable insights paves the way for unprecedented supply chain efficiencies.

When data is harnessed skillfully, a ripple effect of optimization cascades through an entire chain. From inventory management to delivery logistics, real-time data analytics can be a game-changer, infusing vibrancy into an otherwise static chain.

Inventory Management: Data’s Ground Zero

Every seasoned entrepreneur knows that inventory management is the backbone of any business. Balancing efficiency and effectiveness, data analytics fine-tunes inventory management by identifying patterns and predicting demand.

From facilitating accurate forecasting to preventing stock-outs or overstocking, data analytics can send a wave of cost savings and operational efficiency throughout supply chains.

Predictive Analysis: The Clairvoyant Look Into Supply Chain

Predictive analysis, a gem in the crown of data analytics, can transform businesses from reactive entities into proactive powerhouses.

Drawing on historical trends, algorithms project future demand, helping organizations strategize their production schedules, logistics plans, and inventory operations accordingly.

This puts businesses not only on the path of efficiency but also cost-effectiveness and customer satisfaction, too.

Real-Time Logistical Efficiency: Unleashing a Competitive Edge

Leveraging data analytics in logistics propels businesses from reactively managing disruptions to proactively planning routes and aligning resources.

From determining optimal delivery routes to forecasting traffic conditions, data analytics coupled with AI skyrocket logistics efficiency without compromising environmental sustainability.

Risk Management: The Data-Driven Shield

A modern chain is riddled with uncertainty. Market volatility, geopolitical disruptions, or even a pandemic demand a resilient supply chain. Analytics serve as a critical tool for identifying and mitigating risks.

By analyzing historical data, market trends, and potential issues, data analytics provides an opportunity to build a robust risk management framework that is increasingly vital in today’s unpredictable global landscape.

Workforce Optimization: Powering Through People

Beyond machinery and materials, data analytics can unlock the true potential of a business’s most important asset — its people.

By examining workforce data trends, businesses can identify key skills gaps, optimize workforce allocation, and increase employee efficiency.

The Power of Transparency: Fostered by Data

The need for transparency has become an urgent priority for businesses. From adhering to regulatory guidelines to growing consumer demand for clear visibility, data has the potential to empower businesses to showcase their operations, thereby increasing trust and driving success.

In conclusion, the impacts of data analytics on supply chain optimization are profound and transformative. However, the potential is yet to be fully realized.

With advancements in technology and a growing appetite for innovation, the future is ripe for an even greater fusion of data science and supply chain management. An entrepreneur’s ability to wield this potential will determine the market leaders of the future.

After all, in the pitch-black depth of complexities, it’s data that holds the light of optimization. Data Analytics, in full swing, concocts a potion so potent that it transforms the circumference of the modern supply chain optimization beyond recognition.

Fasten your seatbelts, the era of data-powered supply chains is here. With it beckons a revolution that promises unprecedented precision, profitability, and power. The question is, are you ready to ride the wave?

Conclusion

In a world where digital transformation is redefining traditional processes, the role of factors such as data analytics, risk management, and environmental sustainability within the supply chain becomes more pronounced.

These elements position businesses to navigate complex, shifting markets successfully while meeting growing consumer demands for ethical, green operations.

Recognizing the importance of these trends and the implications they could have for their supply chain could offer businesses a path toward a more predictive, flexible, and efficient model.

And while technological progress will continue to drive further changes, it is clear that a comprehensive understanding of these dynamics can form the backbone of a resilient, effective supply chain in the future.

Chris Ekai is a Risk Management expert with over 10 years of experience in the field. He has a Master’s(MSc) degree in Risk Management from University of Portsmouth and is a CPA and Finance professional. He currently works as a Content Manager at Risk Publishing, writing about Enterprise Risk Management, Business Continuity Management and Project Management.