A supply chain key risk indicator (SCKRI) is a metric used to measure, track, and predict risks in the supply chain. Through understanding and monitoring SCKRIs, businesses can make informed decisions about where to allocate resources and take proactive steps to mitigate risks. In this blog post, we’ll discuss what SCKRIs are, why they’re important, and how to use them effectively.

A supply chain is the intricate network of organizations, people, and activities involved in getting goods and services from their origins to their customers. Having a proper understanding of the key risk indicators associated with this process is essential for businesses to make sure that they are managing their supply chain efficiently and effectively.

A variety of factors can come into play when assessing a company’s supply chain risks, including financial, operational, legal, environmental, and reputational impacts. Knowing which risks threaten a business’s success is critical to ensuring continuity throughout the entire value chain.

Kris can help identify potential risks that could have an adverse impact on the supply chain, allowing businesses to take proactive steps to mitigate them. In this blog post, we will explore what KRIs are, how they can be used in a supply chain setting, and the top metrics and KPIs you should track in your dashboards.

Examples of Supply Chain Key Risk Indicators

1. Customer Complaints

Customer complaints are one of the most important KRIs for your supply chain. After all, if your customers are unhappy, that’s a sure sign that something has gone wrong somewhere along the line.

Whether it’s a quality issue with your products or a shipping delay, customer complaints will give you insight into where there are problems in your supply chain. And by addressing those problems promptly, you can prevent them from becoming bigger issues.

2. Vendor Issues

Another KRI to keep an eye on is vendor performance. After all, if your vendors are constantly missing deadlines or shipments are being delayed, that’s going to have a ripple effect throughout your entire supply chain.

3. Inventory Levels

Last but not least, keeping an eye on your inventory levels is important. If you’re constantly running out of stock or have too much inventory on your shelves, that’s a sign that something is off in your supply chain.

Through monitoring inventory levels closely, you can make sure that you’re always stocked up and ready to meet customer demand—without overstocking and tying up valuable resources unnecessarily.

Monitoring inventory levels is a crucial part of supply chain risk management, as high levels of inventory can tie up large amounts of capital and increase the chance of obsolescence.

The ideal inventory level will vary from business to business, but it is important to have a target in mind and to monitor actual levels against this target regularly

4. Lead time variability

This KRI measures the variability in lead times for components and materials arriving from suppliers. This can be monitored using a control chart, with supplier performance being assessed against pre-determined lead time targets.

5. On-time delivery

This KRI measures the percentage of orders delivered on time by suppliers. Again, this can be monitored using a control chart, with supplier performance being assessed against an agreed-on-time delivery target.

6. Backorders

Backorders occur when customer demand exceeds available supply, resulting in delayed shipments associated incremental cost, and unhappy customers. Backorders should be monitored closely as they can indicate problems with forecasting accuracy or supplier reliability.

What are Supply Chain Key Risk Indicators?

Supply chain key risk indicators (SCKRIs) are metrics used to measure, track, and predict risks in the supply chain. SCKRIs provide visibility into potential risks so that businesses can make informed decisions about where to allocate resources and take proactive steps to mitigate risks.

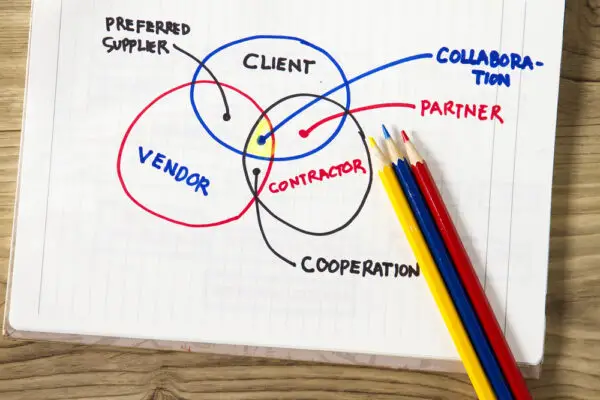

KRIs are divided into customer KRIs, supplier KRIs, and internal supply chain KRIs. Customer KRIs measure customer satisfaction and loyalty, while supplier KRIs assess the performance of suppliers in terms of quality, delivery times, and cost control.

Internal supply chain KRIs focus on tracking key metrics such as inventory levels, lead times, and on-time delivery rates.

In tracking these metrics regularly and taking corrective action when necessary, businesses can ensure that their supply chains remain efficient and productive. This helps them reduce costs and increase profits while minimizing disruptions due to unexpected events or changes in market conditions

Why are Supply Chain Key Risk Indicators Important?

Supply chain disruptions can have a major impact on businesses of all sizes. In fact, a recent study by the Resilinc Corporation found that the average cost of a supply chain disruption is $1.75 million. That’s why it’s so important for businesses to understand and monitor their SCKRIs.

Supply Chain Key Risk Indicators (KRIs) are important because they help organizations identify and monitor potential risks associated with their supply chain operations. KRIs provide an early warning risk mitigation system that can alert businesses to potential problems before they become too costly or damaging. By monitoring KRIs, businesses can take proactive steps to mitigate risk and protect their operations from disruption.

KRIs measure the level of risk in activity and indicate the possibility of future adverse impact. They can also be used to track performance metrics such as on-time delivery, inventory-to-sales ratio, carrying cost of inventory, and more. With this data, businesses can make informed decisions about how to optimize their supply chain operations for maximum efficiency and profitability.

How to Use Supply Chain Key Risk Indicators Effectively

There’s no one-size-fits-all approach to using SCKRIs effectively. The best way to use them will vary depending on the specific needs of your business. However, there are some general best practices that all businesses should follow when using SCKRIs, including:

– Define what constitutes a “risk” for your business. This will help you identify which SCKRIs are most relevant for your business and establish thresholds for each indicator.

– Monitor your SCKRIs on a regular basis. This will help you identify trends and patterns over time so that you can take proactive steps to mitigate risks before they cause significant damage.

– Communicate with your suppliers about your SCKRIs. This will help ensure that your suppliers are aware of your expectations and can take steps to meet or exceed those expectations.

Supply chain management KPIs(Key performance indicators)

KPI #1 – On-Time Delivery and Accurate ETAs

This supply chain kpi provides accurate estimates for arrival are becoming more complicated as shipping volume and destination capacity increase. Getting your ETAs right is essential since your business goods have to be included within another company’s supply chain.

Any hiccup along a full supply chain responsiveness can cause other problems. FourKites provides an innovative supply chain visibility solution that provides predictive and dynamic ETA information for more than 150 factors, including weather, traffic, and stoppages.

KPI #2 – Inventory to Sales Ratio (ISR)

Most accountants would agree that inventory has left no cash behind. The ISR compares your inventory for the same time period with net sales.

This is just the one measure mainly used for balance sheets analysis, which is linked with many other metrics which can help you determine how well your stocks are performing at the moment.

Other ways of calculating inventory balances are subtracting the inventory value from COGS and dividing the value. As the ideal ratio differs according to the industry, it should also be considered when considering your ratio with other firms in your sector.

KPI #3 – Carrying Cost of Inventory

Compared with the ISR cost for supply chain analysis, carrying costs in stock is an important indicator of supply chain efficiency. Transport costs typically range from 20% to 30% of total inventory costs but are dependent on industry or business size.

Calculate inventory carry price using this calculation: Inventory carrying rate x average inventory values. Costs accompany all inventory that you purchase. This cost covers labor, insurance, storage, and incremental cost of transporting goods.

It helps you calculate the maximum profits made using your current inventory by using the above metrics. Indicators for achieving these criteria include low costs and a high enough inventory turnover ratio.

KPI #4 – Purchase Order Tracking

Your order status will definitely be worth tracking. These specific measures will instantly alert you about potential supply chain glitches. They should feature prominently in your KPI dashboard.

The FourKites metrics dashboard tracks purchase orders by order number or supplier by displaying the purchase price. Real-time product information is updated every 15 minutes, with each order colored and highlighted in the order status.

KPI #5 – DSI – Days Sales of Inventory

DSI represents the average time it takes to sell/sell your product. Statistics is important in determining the effectiveness of your company. A very high DSI can suggest a lack of proper inventory management. Or they have been hard to get for sale.

If this happens, make a remediation effort to involve your Sales team – an example of how supply chain KPIs can assist in identifying problem areas. Statistics are reported weekly or monthly based on SKU (stock-keeping unit).

KPI #6 – Freight Cost Per Tonne Shipped

Calculating your freight charges is critical to ensure accurate pricing and minimize operational costs. Some of your freight costs will rise due to a downward trend in freight prices in late February.

Calculating your shipping total costs by unit shipping per month will help in determining how efficiently you are handling these costs. KPIs of the supply chain is determined by modes such as air freight transport or intermodal transportation.

KPI #7 – Perfect Order Delivery Rate

Perfect order rates are externally-facing KPIs. This will help you gain the most sales potential for clients and improve customer satisfaction. These supply chain metrics represent the percentage of perfect orders delivered on total orders delivered.

You define the criteria that will determine if an order is perfect.

How To Take Advantage Of Professional Supply Chain Management Metrics & KPIs

One of the most important metrics to track is the Perfect Order Index (POI). This metric measures how often a company delivers orders on time and in full. A high POI indicates that customers are receiving their orders quickly and without any issues, while a low POI could indicate problems with delivery or customer service.

Another important metric is Cash-to-Cash Time (CTC), which measures how long it takes for a company to receive payment from its customers after an order has been placed. A high CTC indicates that customers are taking too long to pay for their orders, which can lead to cash flow problems for the company.

Finally, Supply Chain Cycle Time (SCCT) is an important metric that measures how long it takes for a product or service to move through the entire supply chain process from start to finish. A high SCCT could indicate bottlenecks in the supply chain process, while a low SCCT could indicate that the process is running more efficiently than expected.

Supply Chain Costs vs. Sales

In general, this indicator estimates supply chain costs based on the percentage of sales you make and will give you the overall amount you spend. When you compute these Supply Chain Management measures, you can perform a good expenditure assessment establishing processes that can reduce costs.

Optimizing Supply Chain is about minimizing costs. As previously stated, cutting costs where they are necessary is important but is not done just because it brings down prices.

Delivered on Time and In Full (OTIF)

The most important supply chain indicator, OTIF, can be found at OTIF. It provides a detailed analysis of the performance of your delivery system for any given period. Your clients’ or clients’ needs are important in your business.

The company has a reputation for delivering quality products in a timely manner, with high accuracy in every aspect of its supply chain. This KPI can help improve your performance.

Inventory Velocity (IV)

Inventory velocity (IV) is an important supply chain measurement measure showing a visual snapshot of inventory consumed during the last day’s sales outstanding upcoming period or quarter. The IV is calculated by dividing the stock opening by sales forecasts for the next period.

Supply Chain Cycle Time

As the key supply chain metric for scaling businesses, supply chain cycle time can be highly informative in terms of measuring your total cost. It provides information about how quickly delivering an order is possible and how much profit is if your inventory is below zero.

The longer a cycle you have, the greater the chain’s agility, adaptability, and efficiency. If you monitor a regular indicator, you may be able to identify the potential roadblocks preventing you from achieving the goals that are needed.

Supply Chain Management Dashboard Examples

A supply chain metrics dashboard is crucial in today’s modern web data visualization, you’ll get stunning data analytics tools with just a couple of clicks. Each of the KPIs of supply chain management is designed to paint an aesthetically pleasing portrait that propels the company toward success in its growth process.

Warehouse KPI Dashboard

For key suppliers, it is important to keep everything in good condition. Keeping an entire inventory is in the right hands can help you manage vital costs in a challenging environment. Critical supply chain kpis including internal and external risks and a supply chain kpi dashboard.

Dynamic KPI Dashboards from warehouses aim to find important insights in real-time in a digestible way. You’ll be able to view on-time shipping costs, calculate total shipping by region or country and break down important operating costs.

Focused data & supply chain insights

Increasing platforms, sources, and touchpoints are required to analyze the fulfillment process and data. Navigating the constantly changing database is easy when managing a complex supply chain.

But a KPI can let you concentrate on what matters to you most. Supply chain metrics visualize what actually counts at a central site in an easily digestible visual form.

Conclusion

Supply chain disruptions can have a major impact on businesses of all sizes—but by understanding and monitoring their supply chain key risk indicators (SCKRIs), businesses can make informed decisions about where to allocate resources and take proactive steps to mitigate risks before they cause significant damage. In this blog post, we discussed what SCKRIs are, why they’re important, and how to use them effectively.

Chris Ekai is a Risk Management expert with over 10 years of experience in the field. He has a Master’s(MSc) degree in Risk Management from University of Portsmouth and is a CPA and Finance professional. He currently works as a Content Manager at Risk Publishing, writing about Enterprise Risk Management, Business Continuity Management and Project Management.